Dry chillers, flooded chillers, falling film chillers difference.

Dry chillers, flooded chillers, falling film chillers difference.

Frequently, customers ask about dry chillers, flooded chillers, falling film chillers, and what are the differences? Today I will talk about the main differences between these three chillers and their advantages and disadvantages to help you understand them.In fact, the three different names are mainly because their evaporators are not used, and their main difference is also their evaporators.

[caption id="attachment_944" align="alignright" width="300"]

Dry chillers, flooded chillers, falling film chillers difference.[/caption]

Dry chillers, flooded chillers, falling film chillers difference.[/caption]The dry chiller is the chiller that we usually see. The refrigerant of the evaporator passes through the heat exchange tube, and the cold water runs outside the heat exchange tube. The advantage of the dry chiller is that the price is relatively cheap, the structure is simple, it is easy to return oil, and the control is also Relatively simple, the injection volume of the refrigerator is small. The disadvantage is that the heat exchange efficiency is relatively low, and the cop is relatively small.

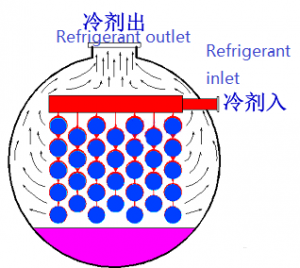

In the flooded chiller and the dry chiller, the operation mode of the evaporator is just the opposite. The cold water passes through the heat exchange tube, the refrigerant completely soaks the heat exchange tube, absorbs heat, and then evaporates after heat exchange. The advantages of flooded water chillers are high heat exchange efficiency and higher cop, but there are also many shortcomings. Its price is more expensive, the structure is complex, the failure rate is higher, and the injection amount of refrigerant refrigerant oil is also ordinary dry type The chiller is more than doubled, and the frequency of adding refrigerant and replacing the freezing oil is also higher, which greatly increases the maintenance cost.

Falling film chillers are also called spray chillers. The refrigerant of the evaporator of the falling film chiller is sprayed from the upper part of the heat exchange tube onto the heat exchange tube. The refrigerant only forms a thin layer on the heat exchange tube. The thin liquid film of refrigerant is poured on the heat exchange tube like a waterfall, so that the refrigerant reduces the static liquid level pressure when boiling and evaporates, thereby improving the heat exchange efficiency. The falling film chiller in these three chillers is replaced The highest thermal efficiency. The disadvantage of the falling film chiller is its high price, and the evaporator is easy to scale and not easy to clean. Usually, the falling film chiller is used in a centrifuge with a large cooling capacity.

Most of the commonly used chillers are dry chillers, which are affordable and have stable performance. Dry chillers can meet the needs without special requirements. Such as flooded water chillers and falling film chillers are usually used in large-scale factory space refrigeration hotel commercial central air conditioning system.

Geson chiller product range covers Industrial Refrigeration and Commercial Central air-conditioning, including Water-cooled chillers, Air-cooled chillers, Screw chillers, Scroll chillers, Centrifugal chillers, Water(ground) source heat pumps, Air source heat pumps and etc., Capacity from 2tons~4000tons, and temperature from -160℃~30℃, complete full product series for customers.

Read more, pls visit www.linkedin.com/in/gesonchiller

I'M NOW FULFILL FINANCIALLY BECAUSE OF THE LOAN I GOT FROM LFDS .I would like to bring this to the notice of the public about how i came in contact with LFDS after i lost my job and being denied loan by my bank and other financial institution due to my credit score. I could not pay my children's fees. I was behind on bills, about to be thrown out of the house due to my inability to pay my rent, It was during this period my kids were taken from me by foster care. Then i set out to seek for funds online where i lost $3,670 that i borrowed from friends which i was rip off by two online loan companies. Until i read about:Le_Meridian Funding Service (lfdsloans@outlook.com / lfdsloans@lemeridianfds.com) somewhere on the internet, Still wasn't convince because of what i have been through until a relative of mine who is a clergy also told me about the ongoing loan scheme of LFDS at a very low interest rate of 1.9%% and lovely repayment terms without penalty for default of payment. I have no choice than to also contact them which i did through text +1-989-394-3740 and Mr Benjamin responded back to me That day was the I'M best and greatest day of my life which can never be forgotten when i receive a credit alert of $400,000.00 Usd loan amount i applied for. I utilized the loan effectively to pay up my debts and to start up a business and today i and my kids are so happy and fulfill. You can as well contact them through email: (lfdsloans@outlook.com / lfdsloans@lemeridianfds.com) WhatsApptext helpline: +1-989-394-3740 Why am i doing this? I am doing this to save as many that are in need of a loan not to be victim of scams on the internet. Thanks and God bless you all, I'm Oleksander Artem from Horizon Park BC , Ukrain.

回复删除